What We Do

From raw sewage to clean water, energy recovery, and digital optimization — discover the full WiTech process.

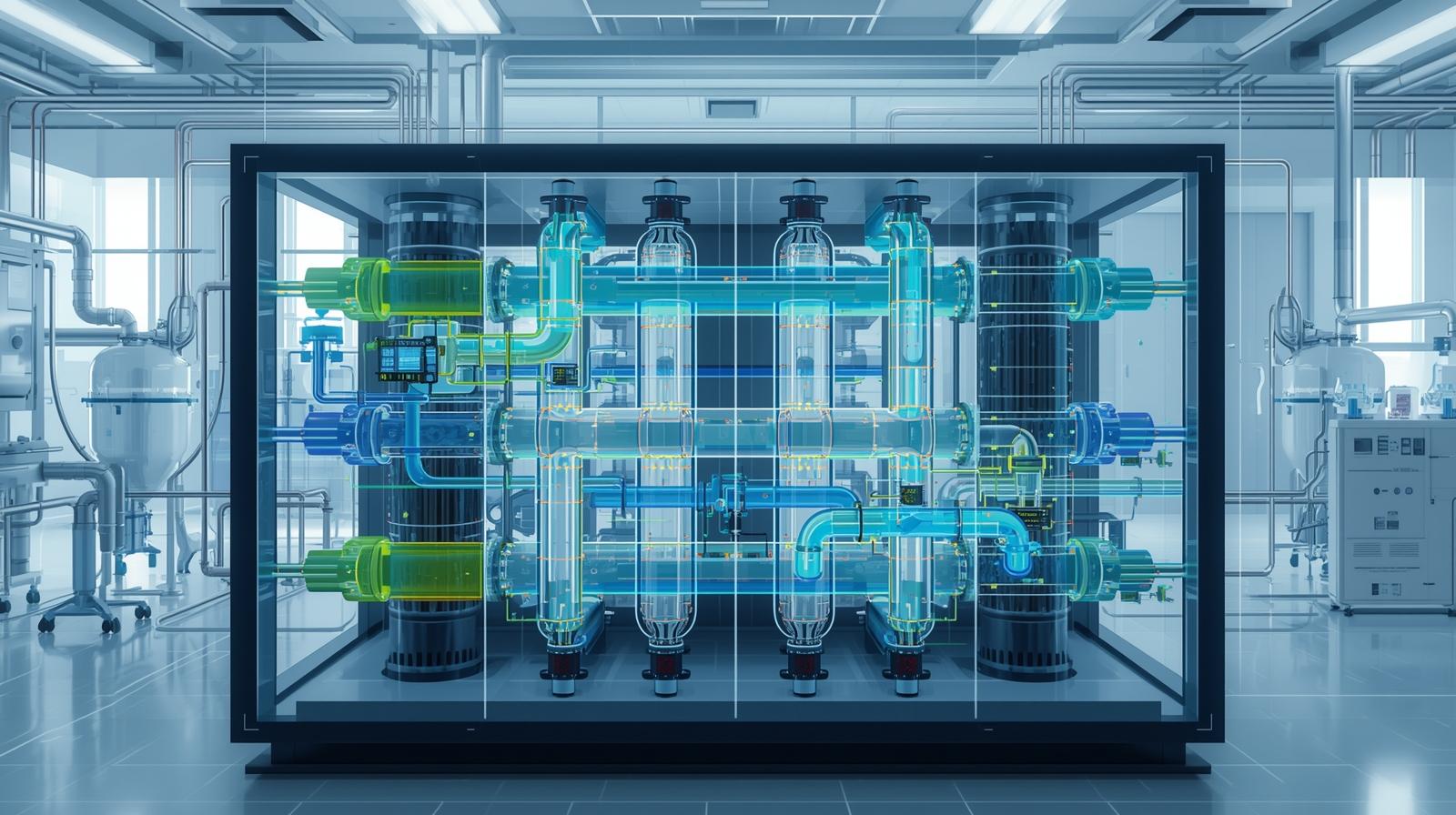

Explore Our Sustainable ProcessModern Wastewater Facilities — Overview

Wastewater facilities collect, convey, treat, and return water to the environment or reuse it. They manage solids, recover resources — water, biogas, heat, and energy — and combine mechanical, biological, and digital layers for efficiency, resilience, and sustainability.

Step-by-Step Process & WiTech Involvement

Step 1 — Collection & Conveyance

What happens: Sewage and industrial effluent collected via sewers or pumps.

Key equipment: Sewers, lift stations, coarse screens.

WiTech role: Flow profiling, retrofitting smart lift stations (VFDs + sensors) to reduce power and prevent overflows.

.jpg)

Step 2 — Preliminary Treatment

What happens: Large debris and grit removed to protect downstream equipment.

WiTech role: Specify robust screens, install blockage sensors, optimize grit removal.

.jpg)

Step 3 — Primary Treatment

What happens: Solids settle in primary clarifiers; oil and scum removed.

WiTech role: Hydraulic modeling, automated desludging control, energy reduction.

.__WiTech role_ Optimize aeration, implement compact systems (MBR, MBBR) as needed..jpg)

Step 4 — Secondary Treatment

What happens: Biological processes remove dissolved organics (BOD/COD).

WiTech role: Optimize aeration, implement compact systems (MBR, MBBR) as needed.

Step 5 — Tertiary Treatment / Polishing

What happens: Remove nutrients, pathogens, micropollutants. Prepare for reuse or high-quality discharge.

WiTech role: Nutrient removal design, membrane integration, sensor-driven chemical dosing.

light or chlorination rays actively eliminating microscopic pathogens from flowing.jpg)

Step 6 — Disinfection & Reuse / Discharge

What happens: UV or chlorination to kill pathogens; water reused or discharged.

WiTech role: Validate reuse quality, design storage & distribution, advise permitting.

Step 7 — Sludge Handling & Biosolids

What happens: Sludge thickened, dewatered, treated anaerobically; biosolids & biogas produced.

WiTech role: Design digestion + dewatering, size CHP/biogas, recommend reuse/disposal.

Ongoing — Monitoring & Digital Control

What happens: Continuous monitoring of flows, quality, equipment, and energy via SCADA + sensors + analytics.

WiTech role: Provide sensors, digital twin/analytics, predictive maintenance, subscription monitoring.